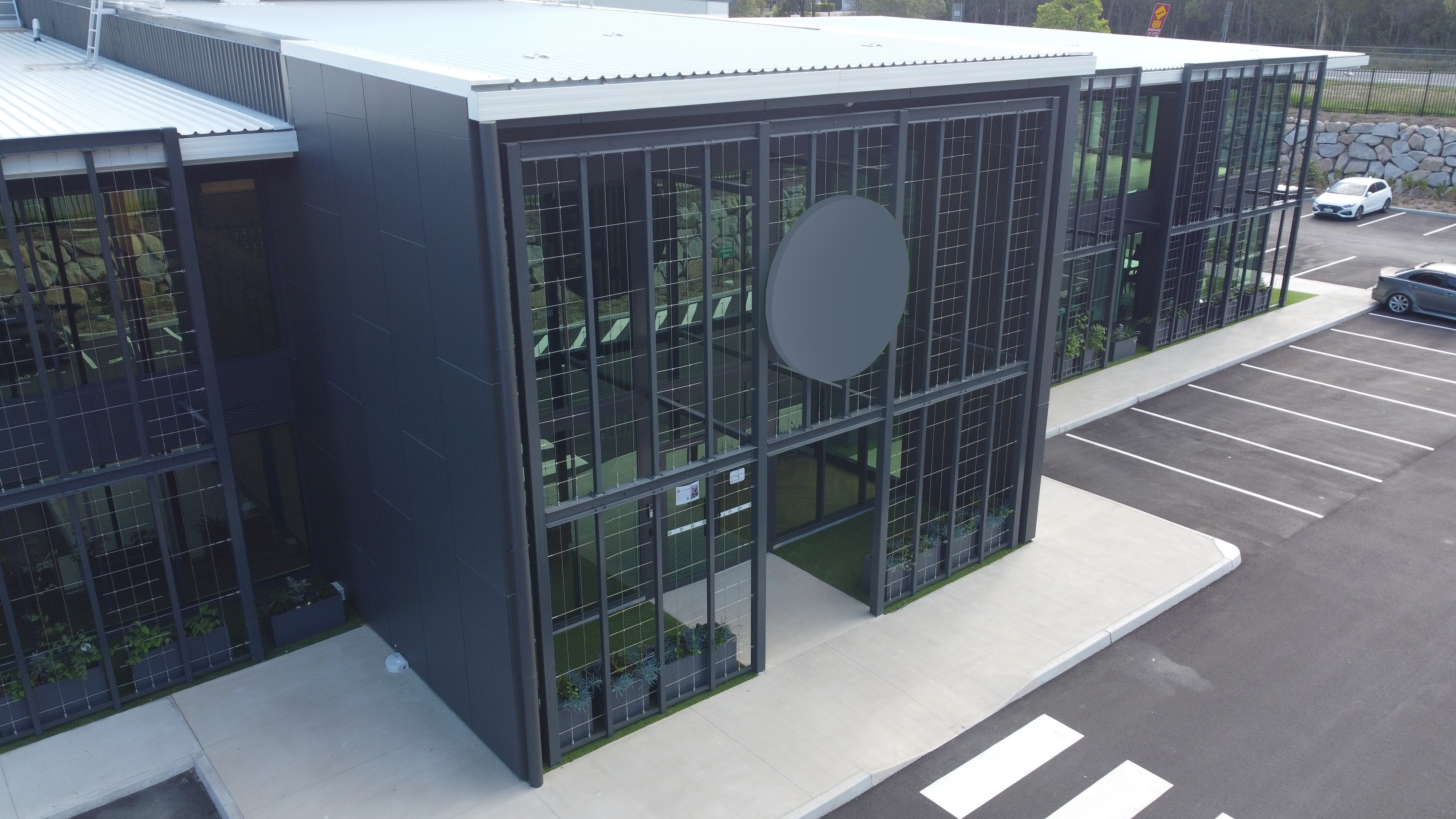

Brisbane, Queensland – Wiley, are proud to announce the successful completion of a multi-purpose ready meals processing facility in Berrinba Logistic Estate, Southwestern Brisbane, Queensland.

The greenfield project took 2 years of careful planning and site selection with Wiley’s team working closely with the client to identify their requirements and scope their integrated facility. Once settling on the optimum site the project involved a tripartite delivery model with leading industrial land developer Logos on their new Berrinba Logistic Hub.

The project at involved designing and building a bespoke, environmentally friendly facility that incorporates 7,000m² of complex processing and services, 400m² of frozen storage, 3,100 critical refrigerated space (2-4 degrees C), and a 2,500m² administration facility.

The state-of-the-art facility was designed to increase operational efficiencies for the client who are a game-changing ready meals supplier. Wiley consolidated three production sites into one and integrated the client’s in-house marketing, administration, distribution, and operations functions into a single operational site. As a result, the facility is scoped to allow the client to increase their weekly output from 400,000 meals to 1.2 million in time, with significant growth potential for the company.

The new operation not only includes such a large operational environment but also integrates environmentally conscious options and allows for future expansion of these sustainable initiatives; LED lighting, rainwater harvesting, a potential expansion of their initial investment in solar energy to encompass up to 1.8 MW of production, economisers are fitted to the site’s boilers which uses waste boiler heat to pre-heat water thus using less gas.

Despite the challenges posed by a severe labour shortage, supply chain bottlenecks, and over 100 wet weather days during the construction period, Wiley delivered the project safely and on schedule. The delivery of a fiberglass trade waste holding tank was delayed by seven weeks due to post-COVID supply chain rush, but Wiley’s team navigated the issue by designing an in-situ concrete tank with plumbing contractors and engineering teams. Structural steel was held up after floods forced the closure of the Brisbane Port, but Wiley’s team responded by altering the construction sequence to allow works to continue. When the ship finally docked, the fabricator made alterations to the steel, reducing the installation time from a scheduled eight weeks to five.

The client’s senior leaders said “Once commissioned, the new facility will materially increase our capacity for growth, improve efficiency, deliver world-class food and employee safety, and achieve improved energy efficiency and environmental sustainability through a modern purpose-built design. And in bringing all our Brisbane-based employees under one roof, we expect significant employee culture and collaboration benefits.”

Wiley’s Operations Manager, Tom Wilson said “our client was great to work with as they presented a number of challenges that our food engineering and design teams are ideally suited to. The client’s need for a consolidated production facility that was operationally efficient, high hygiene, and would future proof their operations made for an outstanding project.”

Mr Wilson continued, “Our ability to work in a collaborative contracting model while addressing the needs of both the end client and the developer in Logos shows how clients, head contractors and developers can work closely to achieve great things in the production precincts surrounding our urban areas.”

Brisbane’s Lord Mayor, Adrian Schrinner, present for the opening said “(this) world-class manufacturing facility is a testament to what is possible when homegrown Brisbane businesses attract new investment and collaborate with strong partners.”

The new facility empowers the client to continue their growth and operational excellence and provides opportunities for them to continue to innovate and disrupt the ready-meals sector.