This article was first published in Food and Drink Business. You can read the original here.

The Northern Co-operative Meat Company Ltd (NCMC) is a co-operatively owned service provider with a long tradition in maintaining and enhancing the manufacture, marketing and distribution of the finest quality food products to the world. The Co-operative is recognised globally as an industry leader in red meat processing and it is held in high esteem by its peers. NCMC has recently undergone significant project upgrades across their business through a number of project delivered by Wiley.

In this article, we will explore the cold chain management system portion of the project, which has allowed NCMC to manage the cold chain requirements through best practice from the boning room to loadout.

Cold chain management is a critical element of any food processing business. This sector is continually contending with additional challenges, from the variety of quality standards in the various markets to continually increasing regulations. The cold chain is also facing many of the same matters that challenge the entire supply chain: serving a global market, being more strategic, driving out costs, and tackling capacity and resource constraints, all while managing the needs of the product.

With that in mind, it’s no wonder that NCMC placed an emphasis on their cold chain management system while completing recent major upgrades at their facility in Casino, NSW. The cold chain management system at NCMC comprises of an automated storage and retrieval system, plate freezing capacity, blast chill tunnel and full ‘cold chain compliant’ loading dock facilities. Here we will focus on the automated storage and retrieval system (ASRS) and loading docks as this is where the business gained added value.

Handling Change

Due to the nature of the NCMC business the company produces a large range of product and volumes; this has in the past required a greater amount of product handling than is ideal.

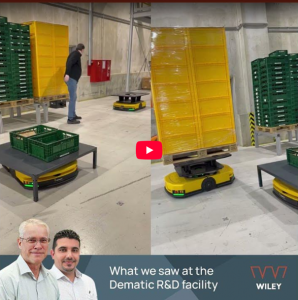

The ASRS supplied by Dematic for installation into the facility designed and delivered by Wiley, allows NCMC to better manage product flow by being able to place small order SKU’s (those products that are less than a full pallet) in the storage facility and fill the pallet when sufficient numbers are produced, significantly reducing the amount of manual handling. This installation is the first ASRS in a frozen environment in Australia and only the second in the World.

The system is capable of handling more than ten thousand cartons per day. Cartons are stored in a single aisle of racks and retrieved using a shuttle system that largely reduces the need for forklifts and manual handling. The system was designed to allow for easy capacity expansion by the addition of further multishuttle racks.

The ASRS combined with the conveyors allows NCMC meat processors to improve efficiencies in chilling and storage, reduce manual handling to improve worker WHS and extend shelf life of products.

Dock Rethink

Another challenge on the NCMC project was achieving complete cold chain compliance in relation to the load out. The challenge was combining the functionality of two distinct dock functions into one multi-use dock. The complying dock needed to service both semi-trailers and container trailers, a task that had not been achieved anywhere else previously.

In a first for Australia, the loading dock system accommodates both shipping containers and pantech trucks (refrigerated trucks that have hard wall freight hulls) in a fully sealed, refrigerated environment. Each loading dock has an ‘igloo’ that the truck reverses into and a seal encloses the access point to the back of the truck, and now containers, to maintain full cold chain compliance. This development we believe will soon become the norm for the industry.

Containing Challenges

The technical difficulty arrived around the type of dock leveler that was utilised by each vehicle and arrangement of the ‘igloo’ (the building structure) around it. Usually, to use a container leveler with a semi-trailer, it does not drop low enough to allow the trailer doors to swing over it and is too wide to avoid clashing with the doors during its operation. In this scenario a semi-trailer is required to open its doors prior to docking and controlling the temperature, hence the container leveler cannot achieve a cold chain compliance.

The solution for NCMC was to incorporate changes to the container leveler and igloo construction to achieve complete cold chain compliance.

Wiley have finalised the distribution end of the business to provide NCMC with a complete upgrade that caters to their unique business model and provides opportunity for flexibility and growth.

NCMC has achieved significant improvements with their recent expansion projects. The company continues to play a prominent part in developing improvements in the area of cold chain management.